How Roar Solutions can Save You Time, Stress, and Money.

( Area 0, 1, or 2). This variant will additionally affect the resourcing demands for job prep work. When Whole lots are defined, you can develop sampling plans based on the sample size of each Great deal, which refers to the variety of random equipment products to be examined. To identify the needed example dimension, 2 elements need to be evaluated: the size of the Lot and the classification of evaluation, which suggests the degree of initiative that should be applied( minimized, normal, or enhanced )to the evaluation of the Great deal. By combining the classification of examination with the Lot dimension, you can then develop the ideal being rejected standards for a sample, suggesting the allowable variety of defective items located within that example. For more information on this procedure, please describe the Energy Institute Guidelines. The IEC 60079 conventional advises that the maximum period in between evaluations ought to not exceed 3 years. EEHA examinations will certainly likewise be performed outside of RBI projects as component of scheduled upkeep and devices overhauls or repair services. These evaluations can be credited toward the RBI sample dimensions within the impacted Great deals. EEHA inspections are performed to determine faults in electric devices. A weighted scoring system is important, as a solitary tool might have multiple faults, each with varying degrees of ignition danger. If the combined rating of both inspections is less than twice the mistake score, the Whole lot is considered appropriate. If the Great deal is still thought about inappropriate, it must undertake a full inspection or validation, which may trigger stricter examination methods. Accepted Lot: The root causes of any mistakes are identified. If an usual failing mode is located, additional tools may call for evaluation and repair. Mistakes are categorized by extent( Safety and security, Integrity, Housekeeping ), guaranteeing that immediate problems are examined and addressed quickly to minimize any type of influence on safety and security or operations. The EEHA database must track and tape the lifecycle of faults along with the rehabilitative actions taken. Implementing a robust Risk-Based Inspection( RBI )technique is crucial for making sure conformity and safety in handling Electric Tools in Hazardous Locations( EEHA). Automated Mistake Rating and Lifecycle Monitoring: Easily handle mistakes and track their lifecycle to improve evaluation precision. The intro of this assistance for risk-based examination better enhances Inspectivity's setting as a best-in-class solution for regulatory compliance, along with for any asset-centric evaluation usage instance. If you are interested in finding out much more, we welcome you to request a presentation and discover just how our option can change your EEHA management processes.

With over ten years of mixed Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to advertise the importance of capability of all personnel associated with the Hazardous Area area in 2019. In 2021, our collaboration with IndEx and Tech Ability International (TSI) marked a milestone in the Saipex road to proceed redirected here Ex-spouse renovation.

A Biased View of Roar Solutions

In regards to eruptive threat, a dangerous location is a setting in which an eruptive environment is existing (or may be anticipated to be present) in amounts that call for unique safety measures for the construction, installation and use of tools. In this article we check out the obstacles faced in the workplace, the risk control procedures, and the required expertises to function securely.

It issues of modern life that we produce, keep or manage a series of gases or fluids that are deemed combustible, and a variety of dusts that are considered flammable. Roar Training Solutions. These substances can, in particular problems, form eruptive atmospheres and these can have significant and heartbreaking repercussions. The majority of us recognize with the fire triangular eliminate any among the 3 elements and the fire can not take place, however what does this mean in the context of hazardous areas? When breaking this down right into its easiest terms it is essentially: a combination of a certain quantity of launch or leak of a particular material or product, blending with ambient oxygen, and the existence of a source of ignition.

This is then validated through inspection and screening and is preserved throughout the life of the setup by using the right upkeep techniques, supplemented by routine assessment. When all these procedures are taken, they ought to also be documented. The confirmation file includes info such as the dangerous area category drawing, makers' documents, equipment certification, layout illustrations and computations, inspection records, and records of an individual's expertise and proceeding expert development (CPD), such as by means of ECA's eCOMS software application.

An Unbiased View of Roar Solutions

It is important that pupils comprehend and have an extensive expertise as to just what makes up a harmful area. The trainee needs to additionally know why training is essential before attempting to tackle job or defining tools into a harmful location. These locations are additionally referred to as classified locations and are defined as areas which have a high likelihood of an explosion due to the possible existence of combustible gases, vapors, dusts etc.

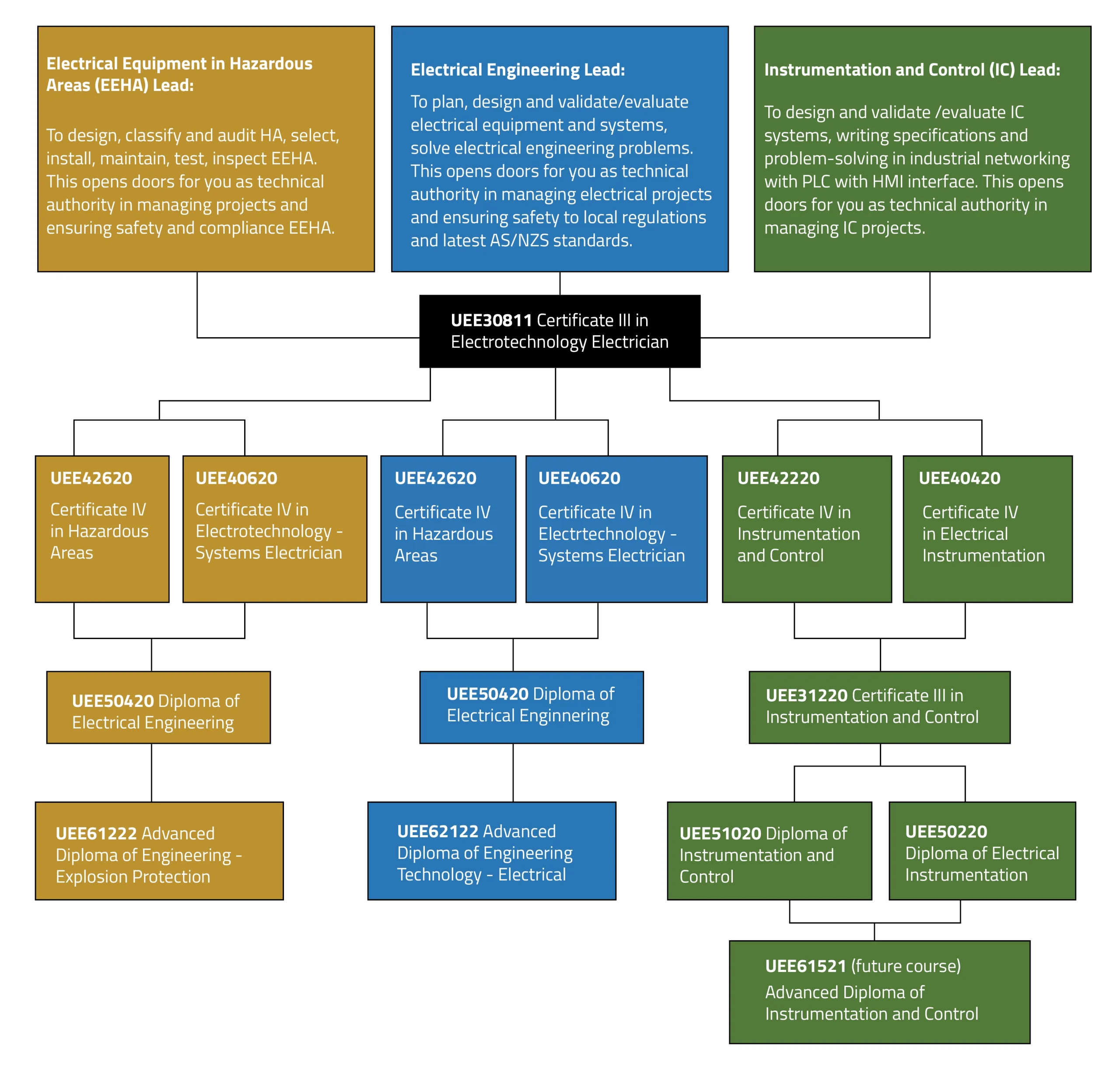

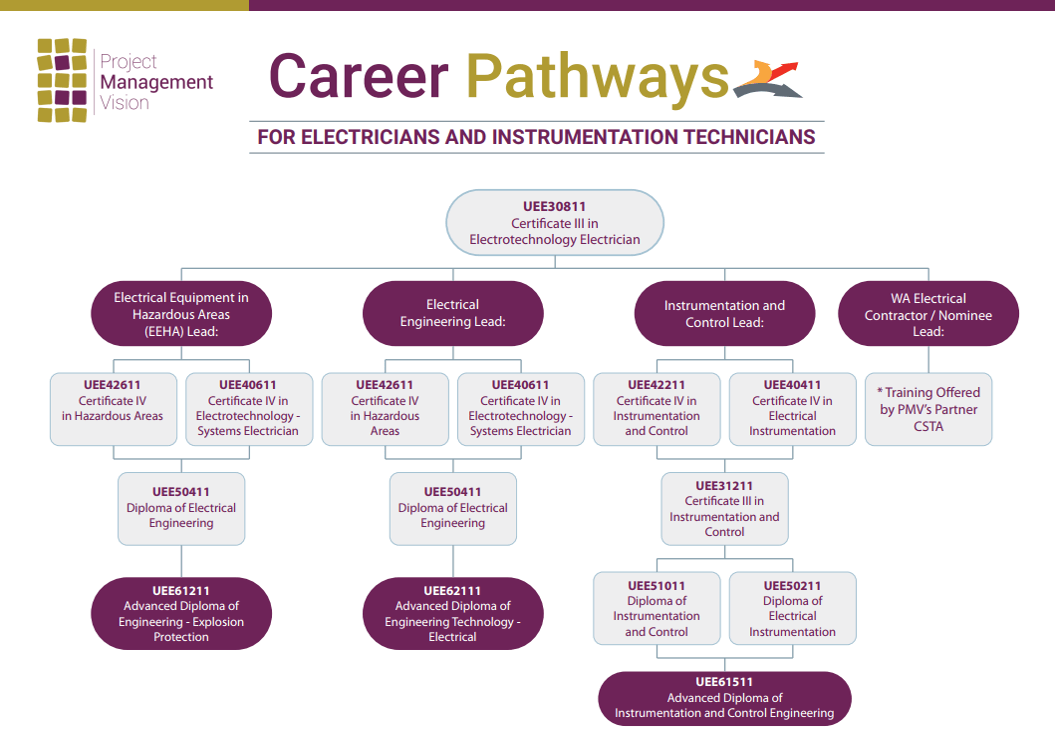

Industries which contain hazardous areas are now demanding that electric workers that are defining or functioning in these areas need to have a hazardous location credentials that regards them competent. Jobs in these sectors are very fulfilling so you need to be prepared. To fulfill this demand for the sector, nationally acknowledged training in Certification IV in Hazardous location Electrical and EEHA training on the development of competent experts.

Our Roar Solutions PDFs

Technology Abilities Australia is a Registered Training Company giving you with one of the most cost effective and quickest method acquiring your qualification - eeha. Our trainers are industry certified and have numerous years of process experience. Our programs have actually helped numerous people from corporate managers to everyday workers in obtaining a strong hold on this not so complex yet high danger training

The training likewise consists of determining the dangerous locations, sources of explosion and the buildings of hazardous materials together with the duties and functions of all events, regulations, systems, standards and method codes connected to harmful locations. We supply instrumentation and unsafe location solutions that remain in compliance to most current AS/NZS and worldwide market criteria.

Comments on “Fascination About Roar Solutions”